Tight Tolerance Copper Coil & Strip

Copper is a critical element in today's world. It's malleable, highly conductive, and anti-microbial. Having long been intertwined in human history, today we still see its role in our everyday lifestyles; from the household to major infrastructure.

We carry several different grades of copper, with the most common shown below:

101

Known as Oxygen-Free Electronic (OFE). It reaches a minimum of 101% IACS conductivity rating. It is the most expensive out of the 101-110 group because of it's composition, 99.99% pure copper with 0.0005% oxygen. C101 specifies trace elements (C102).

102

An oxygen-free copper which has better forming, resistance to hydrogen embrittlement, and brazing characteristics than C110 ETP. C102 has good solder-ability and corrosion resistance and is used for high-current applications.

110

Also known as electrolytic tough pitch (ETP) copper, is used most in electric current-carrying applications. 110 Copper is 99.9% pure copper with an electrical conductivity rating of 100+ % IACS. Conductivity, corrosion resistance, and ductility make 110 Copper very versatile over a broad range of applications.

110 Copper has a poor machinability rating of 20%. It does, however, have excellent hot and cold-forming characteristics. 110 Copper, being a tough pitch copper alloy, is not easily welded or brazed because it suffers from embrittlement when heated in a reducing atmosphere. This occurs because hydrogen reacts with the oxide in the metal to form steam and causes cracking. Oxygen-Free coppers are made for welding operations if needed. 110 Copper can be soldered with good results.

C110 Copper has a broad range of uses, including plumbing fittings, electrical components, wave guides, base plates, bus bars, heat exchanger components, blade and ring terminals, cables, power transmission components, automotive spark plug electrodes, resistance welding electrodes, fuses terminals, and high conductivity items for use at raised temperatures. Both hot and cold forming characteristics are excellent and can be used wherever extensive machining is not required.

151

Alloy C151 has excellent solderability, high conductivity, and good strength. C151 has superior softening resistance compared to pure copper C110, which will soften upon heating, limiting the application environment. Applications can be found in high current interconnects, pin grids, welding wire, or other elevated temperature applications.

194

A first generation high performance alloy used worldwide. C194 combines good electrical conductivity with high tensile strength, good solderability and plateability.

Applications include connectors, semiconductor pins and leadframes, sockets, and mass terminations.

197

A high conductivity copper alloy possessing an excellent combination of strength, conductivity and softening resistance.

This alloy can be substituted for medium tempers of brass and bronze when higher electrical conductivity is required or better solderability is needed.

Alloy C197 is an improved version of alloy C194 and has substantially greater conductivity at the same strength levels.

Work With a Tight-Tolerance Strip and Coil Expert

Partner with Eagle Metals for your tight-tolerance copper coil and strip and watch your operation's efficiency, quality, and profitability soar. Contact us today to request a quote and learn more about our rerolled copper alloy strip capabilities.

additional copper alloy products

High-quality industrial products start with precision materials. Our tight tolerance copper coil delivers the tensile strength you depend on while meeting the most exacting project specifications. As an industry leader, we can supply coils of up to 740 PIW.

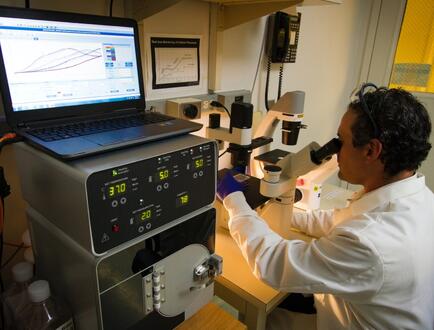

Industries We Serve

We work hard to meet all of our customers specifications in demanding fields and we're ready to meet your most challenging requirements.