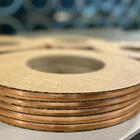

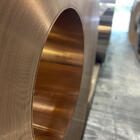

Tight Tolerance Brass Coil & Strip

With a chemical composition of Copper and Zinc, brass remains the go-to alloy for various applications in today's metalforming industry.

Manufacturers of fuses, electrical components, and munitions all utilize brass’s formability or conductivity. Its material strength combined with good ductility make it versatile for numerous uses, and being fairly resistant to corrosion extends the shelf life of this resourceful metal.

Our Brass Products

As a full-service precision reroll mill specializing in brass for over 30+ years, Eagle Metals provides tight tolerance brass coil and strip to our customers made to exacting specifications for countless uses across the globe.

We regularly work with:

210

Most commonly known for its resistance to corrosion. The alloy also lends itself to deep drawing such as bullet jackets and electrical applications where formability and conductivity are required.

Typical uses are for architectural ornamental trim, emblems, plaques, connectors, rotor bars, AC motors, fasteners, bullet jackets, fuse caps, firing pins, and coins.

220

Known for having very good corrosion resistance, great cold workability and good hot workability for drawing, blanking, coining, stamping, piercing and punching.

Typical uses include plumbing brass, small arms cartridges, cable wrap, marine hardware, flexible tube, blots, screws, wave guides costume jewelry and kick plates.

230

Known for having an electrical conductivity of 37%, red color, corrosion resistance, excellent formability and moderate strength.

Typical uses include costume jewelry, eyelets, fasteners, conduit, heat exchangers, flexible metal hose, pipe, and couplings.

240

Has excellent ductility, corrosion resistance and strength which allows it to be deep drawn, etched, stamped, blanked and bent.

Typical uses include musical instruments, battery caps, flexible hose, and decorative pieces because of its yellow color.

260

The alloy, also referred to as cartridge brass coil, has good strength but poor stress relaxation characteristics and does not make a particularly good spring material.

Although it has good conductivity, the solderability of the alloy is severely impaired by its high zinc content.

Commonly used for electrical components, electronic parts, and mechanical fasteners.

268

Often used as a less expensive alternative to alloy 260.

Typical uses include eyelets, hardware accessories, automotive radiator cores, and fasteners.

425 (tin brass)

A low zinc-containing alloy with good combination of tensile strength, electrical conductivity, formability and corrosion resistance.

Applications include electrical springs, connectors and terminals.

Capabilities for Brass at Eagle Metals

Eagle Metals specializes in custom quantities, starting at 100 pounds for min order quantities (MOQ) and still able to handle master coils up to 740 PIW.

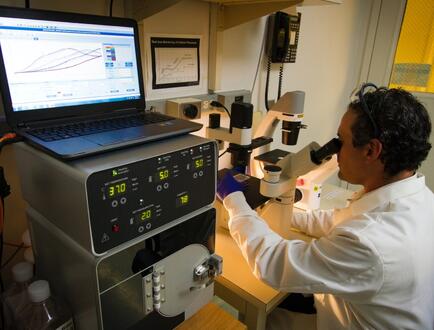

Along with our tight tolerance brass sheet, strip, and coil, we offer several in-house capabilities. We can cut your items to length as well as perform annealing, edge conditioning, slitting, tension leveling, and traverse-winding. We can reduce size, change dimensions, and alter physical and mechanical properties, as needed, to specification.

request a quote today

Eagle Metals manufactures light gauge tight tolerance coils, strips, and sheets. Trusted by precision metal fabricators, we work with a wide range of metals and provide global shipping to meet your needs. We are also a proud member of the Precision Metalforming Association. Contact us to request a quote or learn more about brass options with Eagle Metals.

additional copper alloy products

High-quality industrial products start with precision materials. Our tight tolerance stainless steel coil delivers the tensile strength you depend on while meeting the most exacting project specifications. As an industry leader, we can supply coils of up to 740 PIW.

Industries We Serve

We work hard to meet all of our customers specifications in demanding fields and we're ready to meet your most challenging requirements.